Type: Straightener & Cutter

Situation: New

Use: Sheet

Online video outgoing-inspection: Presented

Machinery Check Report: Offered

Advertising and marketing Type: Sizzling Item 2571

Guarantee of main parts: 3 several years

Core Components: Bearing, Gearbox, Motor, Equipment

Voltage: AC380V(customizable)

Electrical power: 3.75kw

Dimension(L*W*H): 1.6*1.3*1.6

Guarantee: 1 several years

Crucial Offering Details: High Rigidity and easy to work

Relevant Industries: Manufacturing Plant

Showroom Spot: None

Bodyweight (KG): 900

Straightening substance: HR, CR, Stainless metal, Aluminum, Copper and so forth

Substance width: ~800mm

Materials thickness: .5~4.5mm

Straightening rolls: 7pcs(upper 3pcs/decrease 4pcs)

Straightening speed: 1-15m/min

Certification: CE

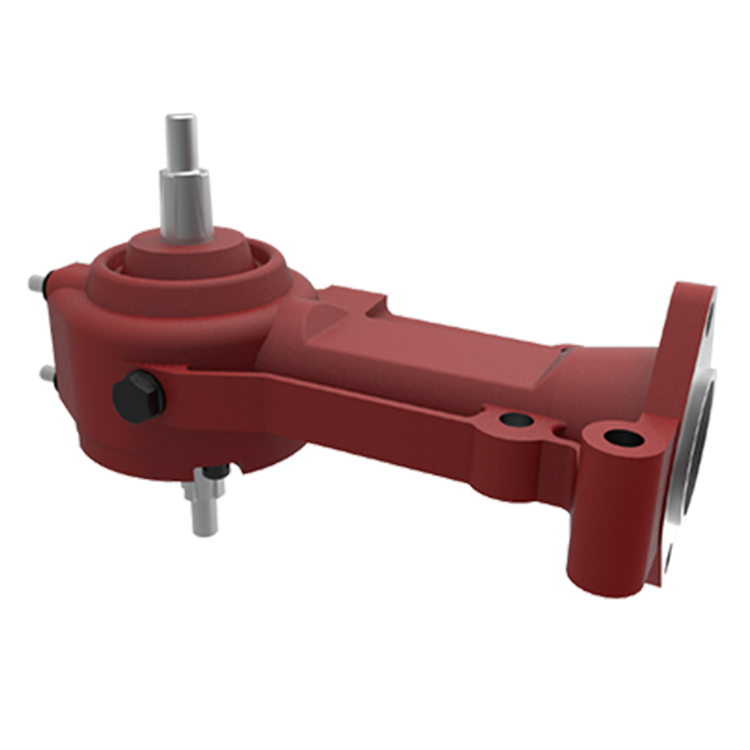

Straightener gap modify strategy: Synchronous worm gear box

Inverter: MITSUBISHI/DELTA

Strip press method: pneumatic cylinders

Roller content: 40Cr

Packaging Particulars: Well wrapped by wrapping movie and packed by plywood box.

Port: HangZhou

IntroductionMetal Straightener, is welded by CZPT steel plate to assemble the composition. With prolonged length fulcrum, so can load weighty excess weight. To lessen speed by “worm wheel” and worm, so that it can work steadily. With induction brake, and with “control time brake” to make it continual for feeding materials. Substantial precision rolls of straightener are plated with hard chrome, with higher straightening precision. Compact whole composition saves making use of place, with resilient attribute.

| Model | SHL-200A | SHL-300A | SHL-400A | SHL-500A | SHL-600A | SHL-800A | SHL-1000A | ||||||

| Material width | 200mm | 300mm | 400mm | 500mm | 600mm | 800mm | 1000mm | ||||||

| Material thickness | 0.5~4.5mm | ||||||||||||

| Straightening rolls | 7pcs(Higher 3pcs/Reduce 4pcs) | ||||||||||||

| Straightening pace | 1-15m/min(with inverter) | ||||||||||||

| Motor electrical power | 1.5kw | 2.2kw | 2.2kw | 3.75kw | 3.75kw | 5.5kw | 7.5kw | ||||||

Principal Attributes1. Match for most of coiled materials, such as HR, CR, aluminium, For Liftmaster Equipment Package 41C4220A Gear & Sprocket Assembly Immediate Substitution stainless metal, copper, and so forth.2. Substantial-hardness and anti-friction rolls are created from heat-dealt with alloy steel with tough chrome plating and precision floor. The material can effortlessly straighten out without scratchs and damages.3. The equipment can perform on its possess, and also can be employed with MT models and MTD types decoiler.4. With powerful motor, CLH designs can attain high-pace feed to lessen costs and increase efficiency.5. The machine adopts large air cylinder pressing content, straightening adjustment adopts synchronous worm gear with reference indicator on the aspect of the body. Turn the deal with for every cycle can change the rolls top 1mm, so as to get higher-precision adjustment. 6. Consumer-helpful control panel and simple structure minimize established-up time and boost efficiency.7. Equipped with inverter, CLH types use a manually adjustable pace handle knob to enable the operator established the payoff pace. (Selection)8. All digital parts are from famous manufacturers in the entire world, this kind of as Simens, Schneider, Mitsubishi. CLh models have longer lifetime and much less maintanence. 9. Personalized and application distinct answer is available.

With substantial expertise and innovative engineering softwares and tools, our engineers can evaluate your software and offer a custom or application specific remedy. Notify us what you require, we are all set to give ideal remedy to you!

Thorough Photographs Our Service Pre-Sales Service* Inquiry and consulting support.

* Offer tailored devices.

* View our Manufacturing facility.

Soon after-Sales Provider* Instruction how to instal the machine, education how to use the machine.

* Engineers available to service machinery overseas.

Certifications Packing & Shipping and delivery Our Organization Professional and InnovationHAIWEI, a expert stamping automation gear company, is a collection of patterns, study & growth, productions and soon after-product sales providers, ninety degree turning curved flat PVC modular belt conveyor situated in HangZhou China. Our items have been broadly utilized in automotive, appliances, furnishings, cookware, components merchandise and other industries. In depth encounter in manufacture and globe-extensive industrial cooperation permits us to offer you with large-high quality tools and first-class service.The vast variety of automatic equipment that we provide which includes 3 in 1 decoiler straightener feeder, 2 in 1 decoiler straightener, decoiler, coil straightener, press feeder, coil blanking line as nicely as all sorts of press transfer which includes Second transfer, 3D transfer, single bar transfer and long beam transfer among multi-press and many others.HAIWEI has been persistently providing market-major items for 10 several years. We are honored to have gained preferred-vendor position with a lot of of the foremost car parts suppliers for Volkswagen, Toyota, Hyundai, Geely, CZPT Bus, IKEA and much more. Increasing demand for substantial efficiency and high quality in production market urges us proceed to enhance R&D potential and machines functionality.HAIWEI is active in world-wide markets with the allow for import and export. We have run lots of productive projects with regional manufacturers in The Czech Republic, Italy, Portugal, Ireland, CZPT large strength manufacturing facility supply Har812 top chains plastic 30mm sprockets company Spain, Canada, Mexico, South Africa, as nicely as Asian marketplaces, this kind of as South Korea, Malaysia, Indonesia, and India.It is our principle to offer superior merchandise and excellent services. The global groups provide you with skilled, swift and handy companies. CZPT aims to source excellent goods and superb companies to develop worth for clients on the foundation of integrity, innovation, and CZPT cooperation. No make a difference what you inquire, we are completely ready to provide the best answer for you!

WHY A lot more FACTORIES Choose CZPT Gear

Extensive Expertise CZPT has been active in international markets for over ten years with the permit for import and export. We have operate heaps of successful creation traces with CZPT producers. The knowledge we accumulate and the obstacle we battle off give the confidence to supply satisfactory options.One-stop Support From design and style to following-sale provider, CZPT sticks to customer-centric principle. Technological help is persistently offered in the course of the complete devices life span. Not only can we manufacture large-functionality products, but we have the capability to layout and product the total automatic generation line.Specific Solution There are electrical engineers, mechanical engineers and application engineers in our staff. Utilizing advanced engineering application and equipment, our engineers can examine your software and offer a customized distinct solution to meet every single unique need to have. In the course of lengthy-standing study and improvement, CZPT results in a extensive variety of complex options, this kind of as high-pace style, space-saving style and multi-language working programDependable Good quality CZPT carries on to control the total supply chain and top quality from raw substance to devices assembly. All devices are certified with European CE. Considerably less routine maintenance and buy cost support you improve efficiency and revenue. Associated Goods Heavy Decoiler91.8% Response Rate

Sheet Steel Straightenerninety one.8% Reaction Charge

NC Servo Roll Feederninety one.8% Reaction Fee

Worm gear reducer gearbox

Cheaper than planetary gearboxes In many cases, worm gear reducer gearboxes are a popular alternative to planetary gearboxes. A worm gear reducer gearbox is a mechanical device with vertical input and output shafts. This allows for very high reduction ratios. They are typically used in high-reduction situations such as machine tools.

Worm gears are cheaper than traditional gearboxes. They also have many benefits, including noise reduction. The output shaft of the worm gear reducer gearbox is almost 90 degrees from the motor input shaft, making it ideal for high-torque applications.

The worm gear reducer gearbox adopts an aluminum body, which is light in weight and high in operation efficiency. Additionally, they are available with hollow shafts and mounting flanges. In terms of initial cost, worm gear reducer gearboxes are cheaper than planetary gearboxes. In addition, they have better efficiency and longer service life.

Worm drives are also ideal for portable battery-powered lifting equipment. The high gear ratio of the worm gear ensures that it does not reverse drive. The worm gear has a spring-applied brake that holds the motor in place.

Planetary gearboxes are popular among industrial users. The efficiency of planetary gearboxes is important for practical applications.

The compact worm gear unit consists of a housing with an inner cavity. It has two side walls, one on either side of the front cover (13) and one on both sides of the rear cover (14). The front end cap is screwed onto the housing and the inner cavity is accessed through the rear end cap.

The compact worm gear unit can be configured to suit your application. They have many advantages, including saving space and increasing torque. The range includes single-envelope and double-envelope versions, available in a number of different power ratings. Additionally, they are IP65-rated, making them ideal for applications involving high radial or axial forces.

The compact worm reducer gearbox is a simple but effective worm drive. Its worm gear 16 meshes with the output shaft and rotates relatively stably. It also has a front-end cap and rear bearing. This enables the compact worm reducer gearbox to reduce vibration without damaging the output shaft.

Compact worm gear reducer gearboxes are ideal for many applications and offer high efficiency. The compact design means you can mount them on the motor’s flange or base. Its durable construction makes it ideal for a variety of industries. They are extremely durable and can handle high-pressure and washdown conditions. They also come standard with a synthetic shaft.

high efficiency

High-efficiency worm gear reducer gearboxes are ideal for applications that require precision, repeatability, and efficient performance. These reducer gearboxes are designed with state-of-the-art servo motor technology to provide tight integration and an angular backlash of less than two arc minutes. The reduction ratio can be lower if the application requires it.

Rising energy costs have led to an increased focus on the efficiency of drives. In response to this, manufacturers have increased the efficiency of worm gear reducer gearboxes through a number of technical improvements. By minimizing losses from rolling and sliding friction, worm gear reducer gearboxes are more efficient than their counterparts.

The high-efficiency worm reducer gearbox is simple in design and has the characteristics of a compact structure, high-speed ratio, low power consumption, and self-locking. Other advantages of these reducer gearboxes include low noise and long service life. Many also have built-in control systems that allow manual and remote adjustments. They also feature automatic shutdown protection and thermal protection.

High-efficiency worm reducer gearboxes can be used for mechanical acceleration. The input hypoid gear is usually made of steel, while the output hypoid gear is usually made of bronze. Bronze is a soft metal that is good at absorbing shock loads. However, bronze requires work hardening to achieve optimum hardness. For large worm gears, this process can take 300 to 550 hours.

low clearance

A low-clearance worm reducer gearbox is a device used to adjust the speed of a rotating shaft. It uses a worm gear consisting of two members. One worm is at one end of the shaft and the other is at the other end. Both worms are screwed into the synchronous drive structure.

Low clearance worm gear reducer gearboxes can be produced on conventional worm gear production lines without overlapping investments. These units are usually made of soft rubber. Also, they are relatively quiet in operation. These machines are designed so that they are suitable for use in elevators. The softer material in the worm gear also helps absorb shock loads.

The tooth profile of the worm gear is designed to change with the axial movement of the worm. Worms have thinner right teeth and thicker left teeth. As the worm moves to the right, its teeth mesh with the worm gear, reducing backlash.

There are many different types of worm gears. The design of gears depends on many factors, including backlash, thermal design, friction factors and lubrication. Worm gears are made of several different materials. Some different types of materials used in worm gears require special lubrication.

quieter

The quieter worm reducer gearbox is designed to reduce the noise level of the rotating gear motor. The device has more gear teeth in meshing contact with the gears, which helps it run more quietly. In addition to being quieter than other transmissions, it’s also less expensive than its counterparts.

Worm gearboxes can be used for different applications, but they are not as efficient as helical gearboxes. Worm reducer gearboxes are cheaper but less than 90% efficient. Higher gear ratios reduce efficiency, so worm gear reducer gearboxes are better suited for applications that require low-speed torque. The cost of buying a worm gearbox will depend on the horsepower and gear ratios required.

Worm reducer gearboxes are also more comfortable to use than planetary gearboxes. They don’t vibrate and heat up quickly, making them an excellent choice for low to medium horsepower applications. Worm gear reducer gearboxes can be upgraded to improve their performance by combining with other gear trains or gearboxes.

easy to replace

An easily replaceable worm gear reducer gearbox can save you a lot of money. A worm gear reducer gearbox is part of a chain drive and allows you to change gear ratios quickly and easily. Worm gear reducer gearboxes can be easily replaced in a number of ways. It’s a good idea to read the manufacturer’s manual before replacing a worm gear reducer gearbox. Make sure you have the instructions available so you can refer to them in the future.

Worm gear reducer gearboxes offer many advantages, including long service life and low noise. They are also designed with a 90-degree output shaft for easy installation. Another advantage of these gear reducer gearboxes is that they can be used with both solid and hollow output shafts. This means less maintenance and downtime.

Worm gear reducer gearboxes are widely used. Most gear manufacturers have large inventories. Worm gears also have uniform mounting dimensions. Dimensional consistency means you don’t have to worry about matching the shaft length and diameter to the worm gear. You can easily find a replacement worm gear reducer gearbox for your equipment.

When replacing the worm gear reducer gearbox, check the lubricating oil recommended by the machine. If not included, use original gear oil. Be sure to follow the manufacturer’s instructions carefully.

editor by Cx 2023-06-26

Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearbox

Double throat worm gear

Double throat worm gear

Brass worm gear

Brass worm gear